BRUX

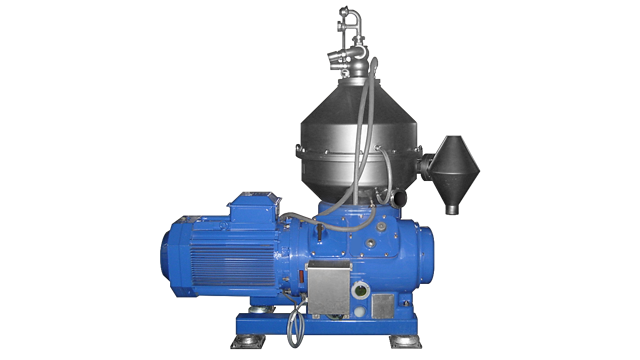

Alfa Laval BRUX, a VLB-validated separator, is specifically designed for continuous in-line removal of surplus yeast as well as micro-organisms and cell debris. The gentle treatment afforded by the low shear forces in the centrifuge maintains high yeast vitality and high quality in the recovered beer, reducing costs. Unique design features ensure highly efficient separation in an automated process operating under strict hygienic standards.

Effective recovery to boost returns

- Efficient and gentle single pass results in high vitality yeast and high quality of recovered beer

- No pick-up of oxygen owing to hydro hermetic seal with added CO2 and de-aerated water

- Short pay-back time as single BRUX module can recover up to 5 million hl a year brewery plant case

- Easy to install owing to compact, modular design

- Low operating costs

Technology

The BRUX nozzle centrifuge has a unique combination of design features that ensures efficient separation in fully automated processes. The unique vortex nozzles automatically assure constant solids concentration at the nozzle outlet at constant solids feed. This self-regulating feature is based on the relationship between the viscosity of the liquid entering the nozzle chamber and the effect of its rotational velocity on the pressure drop. Solids flow rate can be adjusted by choosing different nozzle diameters.

Efficient separation

The BRUX disc-type bowl is equipped with concentrate tubes leading to vortex nozzles. The gravitational force of the bowl forces the yeast (solids phase) outwards into solids pockets at the periphery of the bowl and, from there, through the concentrate tubes and internal vortex nozzles into a paring tube chamber. Once in the chamber, the concentrate is skimmed off by the paring tube and discharged from the separator under pressure. The liquid phase is clarified as it passes through the disc-stack towards the centre of the bowl from where it is discharged under pressure by a paring disc pump at the top of the frame hood.

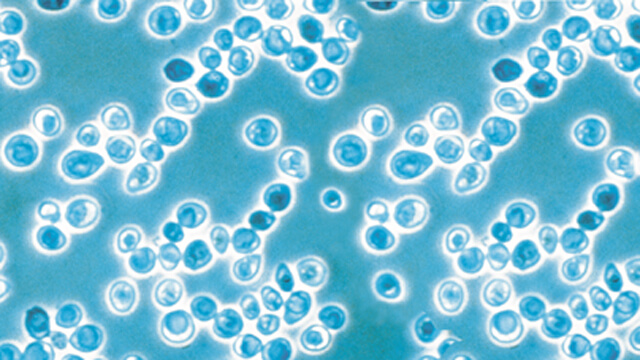

Highest yeast vitality

Due to constant solids discharge through the nozzles (one pass) and low shear forces in the centrifuge bowl, solids treatment is very gentle. The result is the highest yeast vitality of all current beer recovery methods available.

High quality recovered beer

The gentle treatment also maintains the quality of the recovered beer. It is so high that customers report that it can be dosed as 5% of mainstream beer volume downstream prior to final filtration with no adverse effect on final beer quality. Recovered beer can also be dosed back to the hot wort (prior to the wort cooler), fermentation or maturation.

Designed for cleaning-in-place

The BRUX is fully CIP cleanable to avoid bacteriological contamination. During the cleaning cycle, which is carried out with the machine at full speed, a valve slide under the bowl momentarily opens the CIP valves permitting the ejection of solids together with some washing liquid. The system is designed in such a way that solids ejections can be performed in certain intervals. CIP liquid is supplied from central CIP station and is cleaned as a ‘pipe’. Design of machine is such that the module is cleaned with feed and both outlet pipes (beer and yeast) all the way to the tanks in one only loop.

Recover beer from surplus yeast

In general, breweries produce an excess of yeast that corresponds to 2-4% of their total production volume. When collected from the fermentation vessels, this surplus yeast still contains significant quantities of beer. You can read more about the efficiency, practicality and technical details of the BRUX separator modules by downloading the product leaflet.

VLB report

Report to the technological quality validation of the BRUX Yeast Beer Recovery System.

How we can help you?

We don’t offer a one-size-fits-all approach so before we make any recommendations we want to hear your side of the story and speak to your personally about your aims, ambitions and requirements in terms of yeast and beer recovery specifically and your brewery in general.

คุณอาจสนใจ...

To the last drop

Leading brewers are seeking more sustainable ways to better use raw materials and to optimize production by increasing yields and reducing losses, all while maintaining beer quality and expanding production capability. Alfa Laval provides a series of solutions.

การผลิตเบียร์เชิงพาณิชย์

อุปกรณ์ที่ดีที่สุดสำหรับเบียร์ที่ดีที่สุด

การผลิตคราฟต์เบียร์

แบ่งปันความชอบของคุณสำหรับการผลิตคราฟต์เบียร์