Designing individual process steps with vision

Having a broad view of the entire production process allows us to find new ways to improve your operations. We recommend starting by looking at how the individual process steps affect each other as a path to optimize the whole - often finding new, smarter ways to combine equipment.

Scaling up production, not cost - a case story

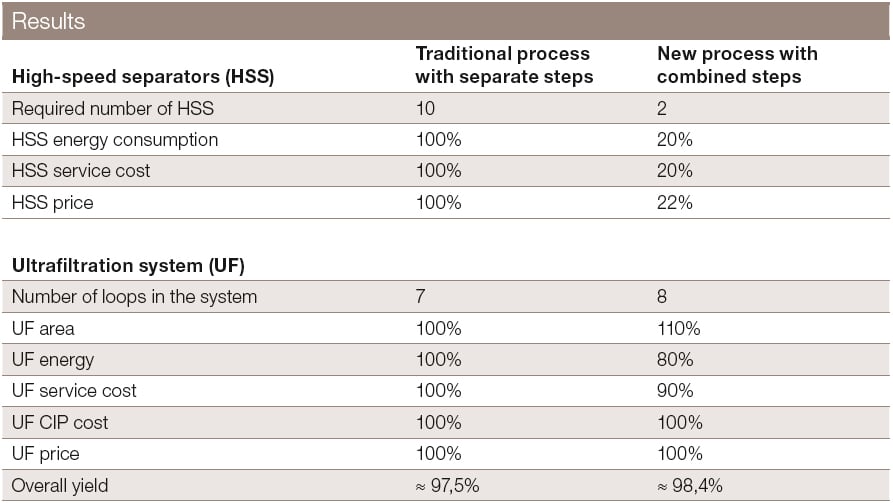

When a producer of organic acids was scaling up from demo plant to full-scale production, Alfa Laval’s engineers designed a cell-removal system that improved yield, and cut both installation and operating costs.

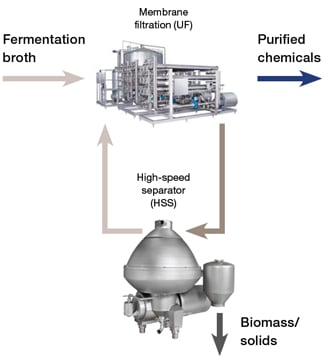

The obvious choice would be to scale up the process used in the demo set-up where the broth was processed in two steps. First, it passed through a high-speed separator where the cells were removed, and then it was purified in a second step using cross-flow membrane filtration. Just scaling up the existing design would have resulted in major investments and high operating costs.

Combining process steps to cut costs

Alfa Laval’s engineers proposed a solution where the two steps are combined into one. Since the amount of cells in the broth is relatively low, it is possible to first run it through a membrane filtration stage where the product is recovered. The concentrate (cells and fluid) then passes through a high-speed separator where the cells are removed. The high-speed separator in this set-up is specially designed for handling liquids with a high concentration of cells.

The clear fluid from the separator is led back to the membrane stage where the product is recovered. To avoid the build-up of accumulated fines that haven’t been removed by the high-speed separation step, the membrane stage has a unique design and an automatic

control system that regulates its operation.

The key benefits of this design are significantly lower investment costs and energy consumption as well as improved yield. The highly concentrated biomass resulting from centrifugation also minimizes the amount of water used for diafiltration and the need to remove additional water later in the process.

Whitepaper: 10 ways to improve your bio-based chemical plant