Alfie

Alfa Laval Alfie centrifugal separators remove oil, grease and solid particles from industrial coolants. They help prevent tool wear, reduce fluid consumption and lower your disposal costs.

Quick, continuous cleaning

- Can be linked to a bypass flow, ensuring less downtime for service

- Disc stack separators provide simultaneous, three-phase separation of oil and sludge

- Designed for operator convenience

- No machinery redesign required

The Alfa Laval Alfie range of compact, high-speed centrifugal separators minimizes operating costs by keeping coolants clean. Systems are fast and effective – helping improve end-product quality and reducing maintenance manhours.

How it works

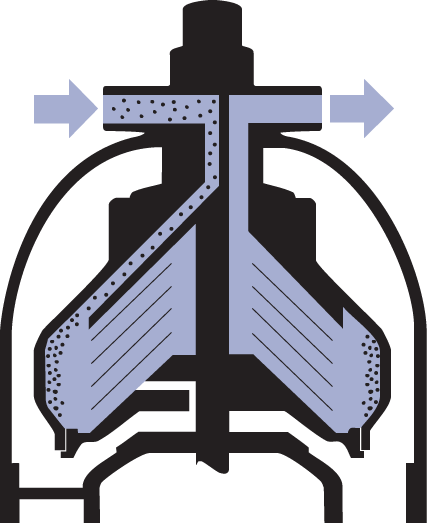

Alfie systems separate phases quickly by using a centrifugal force that's 5,000 times stronger than the gravity used in traditional settling tanks.

The centrifugal force presses heavy particles outwards against the separator walls. The disc stack forces lighter particles to follow the heavier ones instead of the liquid, making separation more precise and efficient.

Choose the ideal system for your application

We offer systems for all types of fluids – whether you're a small workshop or a large factory.

- Alfie 200 is designed for mounting on top of coolant tanks, and is fitted with a bellows that automatically adapts the inlet to the tank's fluid level

- Alfie 500 is a mobile system ideal for smaller applications, with special couplings that make it easy to connect and disconnect hoses quickly