ConditionAlert™ for high-speed separators

Alfa Laval ConditionAlert™ gives you a complete, real-time view of your separator’s health and performance. This advanced condition monitoring system continuously tracks key operating parameters and provides early warnings when attention is needed. As an integrated Alfa Laval condition monitor, it delivers accurate insights to prevent unplanned downtime. Combined with expert analysis from Alfa Laval, ConditionAlert ensures optimal separator performance, reliability, and longevity, keeping your separator running at its best.

Experience the benefits of Alfa Laval ConditionAlert™:

• Reduce downtime

• Reduce maintenance costs

• Reduce number of accident

The value of saving one day’s production

With real-time insight and early warnings, ConditionAlert is a very profitable investment in your business’s uptime.

In the cases below, two businesses in two different industries using ConditionAlert prevented unplanned stops in their production.

| Large brewery (mostly lager beer) | Large refinery (feed stock soy beans) | |

|---|---|---|

| Output | 15000 hl/day | 1250 tons/day |

| Profit loss from one day’s unplanned stop | KEUR 1200-1800/day | KEUR 80-120/day |

| Annual cost of ConditionAlert for three separators vs one day’s profit loss | <1% | <10% |

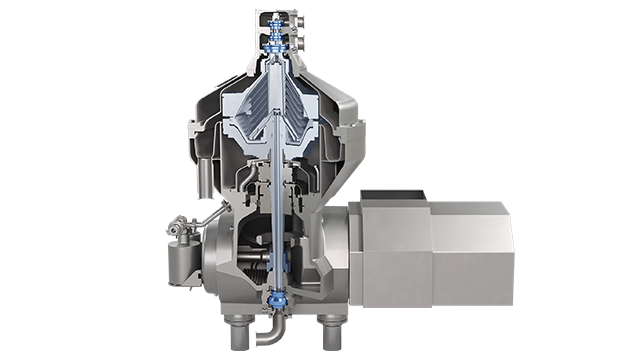

How ConditionAlert™ works

ConditionAlert™ uses built-in sensors to monitor vibration levels and other signals in real time. Through advanced frequency analysis and comparison with Alfa Laval’s global database, it identifies abnormal patterns and pinpoints potential issues. When irregularities occur, early warning messages are sent to you and your local Alfa Laval service team by email or text, allowing quick response and efficient planning.

You can monitor the trends and status of the installed separators’ condition at any moment, in real-time, on a web interface. ConditionAlert can also monitor temperature and other signals to give you additional insights into the condition of your separator.

How to use ConditionAlert™

Use the insights from ConditionAlert™ and the support of Alfa Laval experts to plan maintenance proactively. The system provides early notice of wear in rotating components, helping you avoid unplanned stops, ensure spare parts availability, and safely extend operation between service intervals.

The formula for maximum uptime: an Alfa Laval Service Agreement with ConditionAlert™

Get the most from ConditionAlert™ with a customized Alfa Laval Service Agreement. It includes all necessary services, parts, training, and maintenance planning to keep your separator performing at its best over the long term - built on close, continuous collaboration between your team and local Alfa Laval service experts.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.